Samsung has announced a new 17nm process for products that are now manufactured using a planar 28nm process but could benefit from a move to 14nm FinFET process technology. However, most semiconductor products are now manufactured using less advanced manufacturing processes, and Samsung offers them the opportunity to improve.

Source: anandtech.com

When developing semiconductor components, design standards are always taken into account. Therefore, you can’t just start producing components designed for a 28-nm process technology on more modern 14-nm lines, since they use a completely different approach to the formation of microcircuits, not to mention the differences in the design of the transistors themselves.

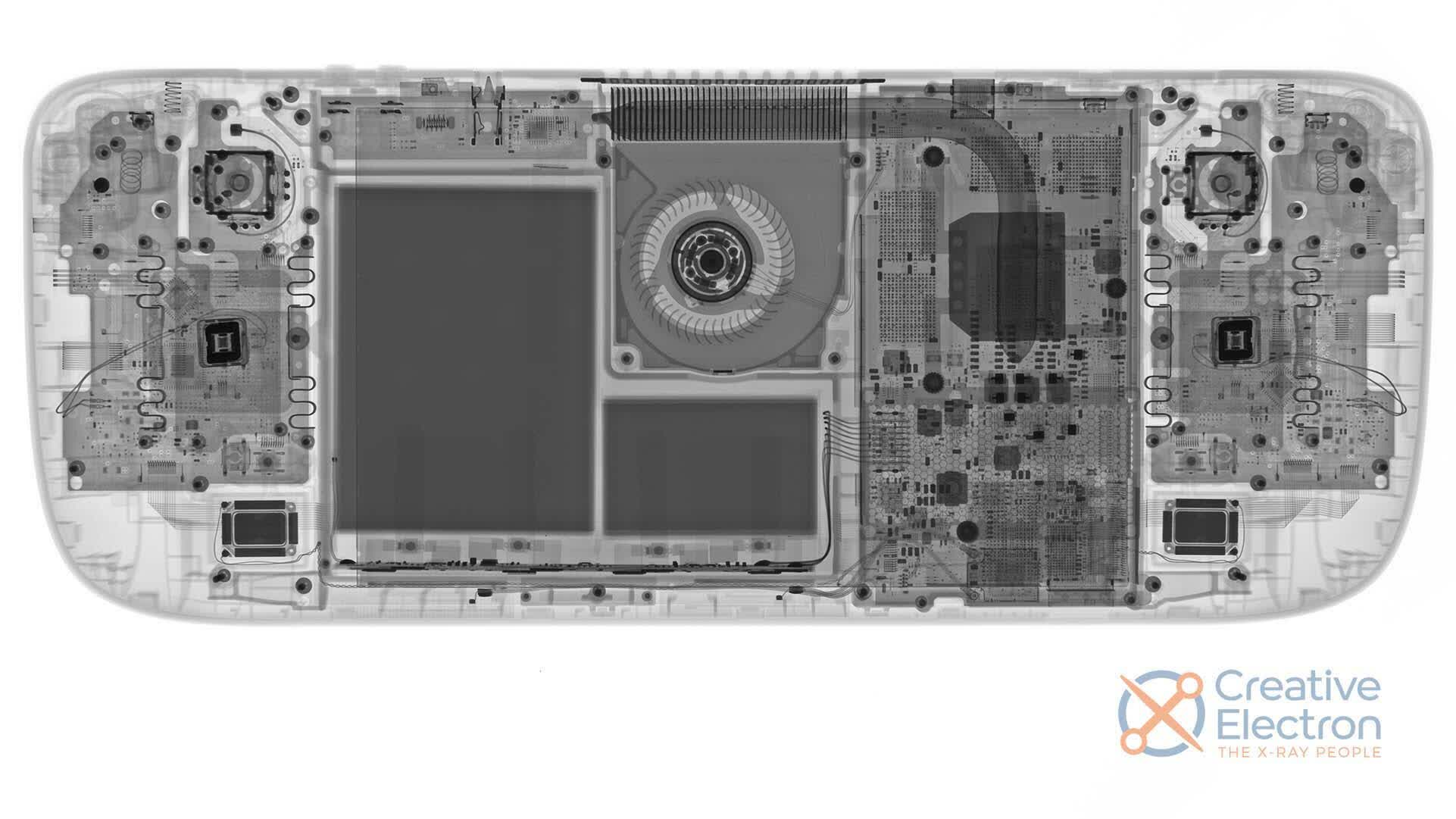

Production takes into account two or three main segments. Production begins with the Front-End-Of-Line (FEOL) stage – the formation of active parts of the crystal. When we talk about advanced technologies, we mean FEOL, which implements the most advanced means of creating silicon cells. This is followed by the Back-End-Of-Line (BEOL) stage – the formation of interconnections and auxiliary connections. Sometimes they talk about the intermediate stage Middle-End-of-Line (MEOL), in which tiny metal structures are formed that connect to the BEOL lines.

When describing technologies, for example, 28 nm, design standards are provided for both stages – FEOL and BEOL. But in some cases, manufacturers combine some FEOL design codes with other BEOLs to create a product line with some characteristics of both segments. This is how the new 17nm 17LPV (Low Power Value) technology, announced at the Samsung Foundry Forum, was implemented.

Source: samsung.com

17LPV technology combines 14nm FEOL (and, accordingly, 14nm FinFETs) with 28nm BEOL interconnects. This means that at an additional cost, customers can benefit from the performance and power consumption of FinFET technology without the additional cost of denser BEOLs. Samsung clarified that 17LPV technology delivers 43% less component area, 39% more performance, or 49% more energy efficiency over its 28nm counterparts.

In practice, solutions based on 17LPV can be used, for example, in signal processors for processing images from a camera, where the maximum density of elements is not required. In addition, Samsung will use technology in the production of displays – on high voltage components.

Samsung also introduced 14LPU (Low Power Ultimate) technology for a similar purpose and probably architecture that will be used in embedded MRAM and microcontrollers. The company has not yet clarified the timing of the introduction of new solutions, however, representatives of Samsung Foundry called these technologies “a paradigm shift” for a company that will improve specialized components.

If you notice an error, select it with the mouse and press CTRL + ENTER.

Note: This article have been indexed to our site. We do not claim legitimacy, ownership or copyright of any of the content above. To see the article at original source Click Here